Over the past 20 years, soft-touch cladding has changed dramatically in terms of its appearance, feel and range of applications. The rich colour, texture and touch make it widely used in toothbrushes, razors, power tools, cameras, kitchenware, handheld electronics and automotive interiors.

The driving force for this change is the increasing diversity of thermoplastic elastomers. In cladding molding, TPE is coated around the structure, giving it the advantage of a hard and soft structure that is tactile, slip and wear-resistant to handles or buttons.

The biggest problem of cladding molding for designers and producers is the bonding between TPE and structural parts. If the bonding is not good, there will be peeling, shrinkage, shedding or stratification at the junction of the two materials. At first, people used a simple method to solve this problem, using olefin TPE and rigid PP with good compatibility for cladding molding.

In recent years, covering the molding materials used by increasingly diversified, TPE, TPU, TPV, SEB different kinds, such as structure using ABS, PC and nylon, the design of the diversity of the material to make the cladding forming the retrofit, but the resulting glue problem between incompatible materials also became cladding forming process of a new challenge, This also makes the cladding more complex.

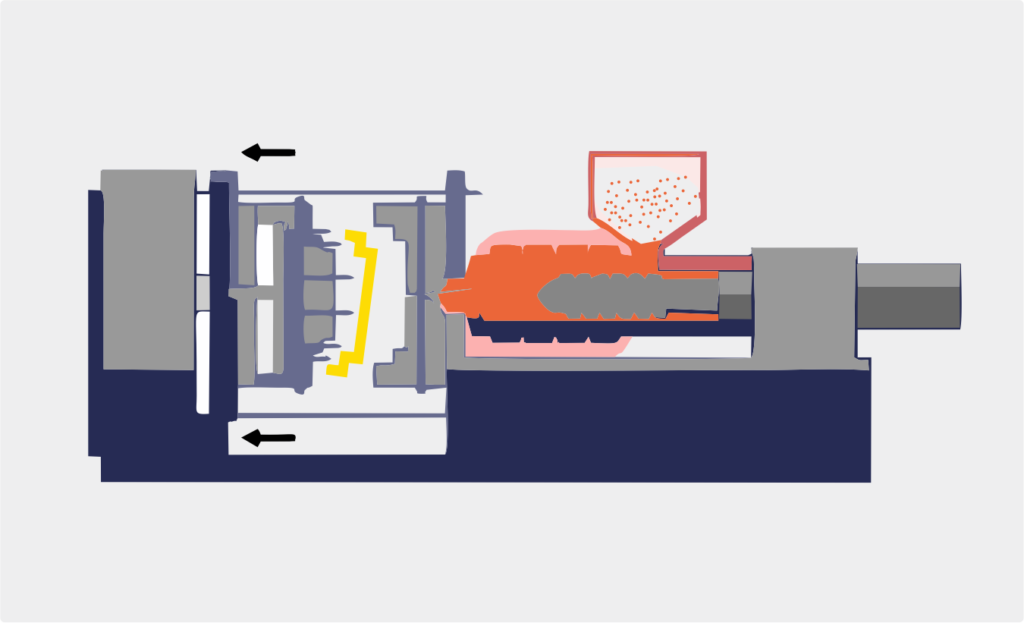

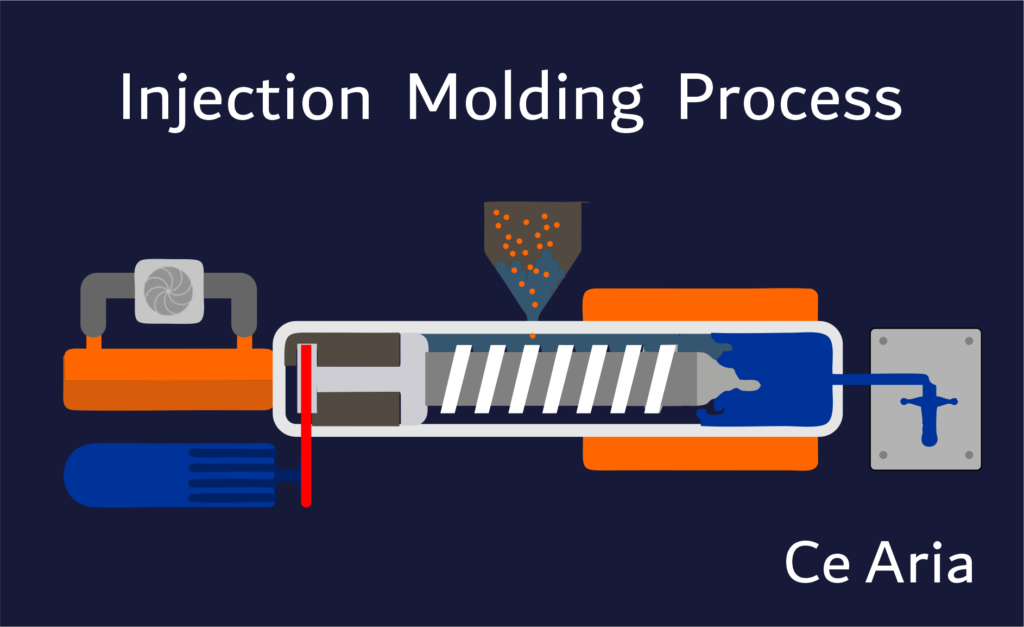

In insert molding, hard structural parts are first molded and then molded again. TPE is injected into the finished structure using standard injection machines and relatively simple, low-cost molds during secondary moulding. Insert molding is suitable for producing relatively small production products, and the low labour cost of the production place makes the insert molding have a certain advantage.

Multi-component injection molding requires using a specialized injection machine with multiple barrels to inject several materials into the same mold, in most cases, two-component injection molding. The advantages of multi-component molding are to reduce production time, improve product quality and reduce the number of labor. The annual output of this method can reach 250,000 or more, which is suitable for areas with high labor costs.

Strength and durability are important parameters for measuring the bonding between TPE and structural parts in all machining processes. The method of cladding molding usually affects the bonding performance, and the bonding performance is also affected by some external factors.

The area between TPE and structural parts in product design is the key to bonding. The contact area between TPE and structural parts should not be too small in product design. TPE’s gradual thinning should also be avoided because the thin TPE layer is prone to insufficient bonding, resulting in the TPE layer falling off. Ideally, the thickness of the TPE layer is about 0.04in.

To solve the TPE overmolding process: A cutoff slot can be designed between the TPE and the structural part. In addition, structural parts may have grooves on which the TPE cutoff may be located. These designs can reduce the possibility of TPE flanging or stripping.

In extreme cases, where the flow path of the melt is very long or the wear area of the product is very large, TPE can be injected into the internal stroke interlocking structure of the structure.

In cladding molding, the air in the cavity has a great influence on the bonding performance between the interfaces, and the solution is to exhaust fully in the mold design. If the exhaust is poor, poor TPE bonding will occur, and even the lack of material will occur. Generally, the depth of the exhaust port is between 0.0005 and 0.001in.

Reasonable pretreatment of inserts is also the key to improving the bonding performance. For example, cleaning inserts can help improve bonding performance. The optimal manufacturing method is to wrap the inserts directly after they are produced, minimising contamination. If this is not possible, the insert should be carefully stored in a dust-free place. Gloves must be worn when handling inserts to avoid grease contamination. In addition, try to avoid the use of a release agent.

Preheating the insert before cladding helps increase the bonding strength because the preheating process improves the compatibility of the insert material with TPE. The reasonable temperature of the inserts should be discussed with the material supplier.

In this paper, TPE and PC structural parts with A hardness of A 65 were coated to reflect the relationship between TPE melt temperature and bonding strength. When the melt temperature increases from 188℃ to 205℃, the bonding strength is improved. However, the bonding strength decreases when the melt temperature increases to 220℃. In this case, the optimal melt temperature is 205℃. To select an appropriate melt temperature, the processor must consider melt strength in conjunction with thermal degradation or injection difficulty.

The process of processing temperature should be slow, do not need to increase the barrel temperature but should be achieved by increasing the screw speed and injection speed. When determining melt temperature, keeping the injection nozzle temperature consistent with melt temperature is not necessary. The temperature of the TPE melt must be measured with a sensitive thermometer.

The determination of melt temperature is related to the structural parts and bonding requirements. Most TPE suppliers list the appropriate melting temperature for their TPE and generally consider the parameters recommended by the supplier when selecting the TPE melting temperature.

The tactility of coated products is related to the hardness, friction coefficient, texture and thickness of TPE.

If the THICKNESS of the TPE layer is less than 0.060 in…, the soft-touch characteristic of the elastomer will be offset by the hard structure. The cushioning of the TPE is related to the hardness of the bottom structure.

In addition, the thickness of the TPE layer also affects the bonding strength. Thin TPE layers excrete heat rapidly in the cold mold cavity, and the decrease in temperature decreases bonding strength. The balance between product hardness and TPE thickness is a design challenge for designers.

Some types of TPE, such as TPU, TPV, copolyester, etc., have a certain hygroscopicity. If they are not properly dried before forming, the water in the material will evaporate out and destroy the bonding properties between the two materials. Moisture can also hydrolyze some kinds of resins, damaging the surface properties of materials and making injections difficult. During injection molding, moisture should be controlled by 0.05%. Usually, TPE is dried with a dehumidification dryer with a dew point of -40 ℃.

Colour masterbatches are used in TPE coating molding. If the carrier resin of the masterbatch is not compatible with TPE, the bonding strength will be affected. TPE usually contains PP, but the structural parts are usually nylon, PC/ABS, or other engineering plastics.

In the use process, the product will be subjected to a lot of friction, so there will be a stratification phenomenon. The gate should be installed at the maximum area of the TPE because the TEMPERATURE of the TPE at the gate is higher than at the end of the melt flow. When the appearance of the product is a priority, such as cosmetic packaging, the gate should be placed behind the structural parts so as not to affect the product’s appearance.

The ratio of the melt flow length to the product’s thickness is a key factor in ensuring that the TPE melt is filled into the cavity. The minimum ratio should be about 150:1. In addition, the gate can also be installed at the thickest part of the product while ensuring that the melt flow length is as short as possible.

In the selection of gate design method, the size of the gate should be designed smaller first and then gradually increased the size until it meets the requirements. Some TPES (e.g. SEB) require a small gate to increase shear force and ensure full mold filling, while others (e.g. TPV and TPU) require a larger gate to cope with their high melt viscosity.

The elements of mold design

Designers sometimes try to emphasize the texture and feel of the product by polishing the mold, but smooth molds can sometimes produce imperfections. Instead, the surface texture of the product often masks these imperfections and gives the product a feather-like feel. A certain surface texture will have a certain impact on the hardness of the product’s surface. The designer’s goal is to balance the surface texture of the product and the hardness of TPE, so that the product can meet the expected requirements.

The product should be 0.5° ~ 1° is appropriate. For some difficult to inject materials, such as TPU, need to design 5° ~ 6° of the drawing die. The texture of the die surface usually improves injection performance.

Bonding properties of nylon

Nylon is increasingly used in the structural parts of cladding, such as the handles of power tools. But nylon and TPE adhesion performance is not good, and TPE and added glass fibre nylon adhesion is relatively better but needs to add other additives.

There are many kinds of nylon, such as nylon 11, nylon 66, nylon 12, enhanced nylon, etc. The bonding strength is low when TPE is coated with impact-resistant nylon and thermal stable nylon 6. However, the adhesion between TPE and nylon will be greatly improved after improvement.

In addition, nylon is hygroscopic, so it needs to be dried before processing. The melting temperature of nylon is relatively high, so the melting temperature of TPE needs to be increased accordingly to ensure better bonding between the interfaces of the two materials. Usually, nylon inserts need to be preheated. In addition, the carrier resin of the masterbatch should also be carefully selected. Usually, LDPE and EVA have good compatibility with nylon.

10 elements of Overmolding:

- Compatibility between TPE and structural parts should be matched

- Sharp corners should be avoided as far as possible in the design

- Proper exhaust is used to avoid gas retention in the mould cavity

- Balance the thickness of TPE with the desired tactile sensation

- Keep TPE melt temperature to optimize bonding

- Dry moisture sensitive material

- The selected masterbatch carrier resin is compatible with TPE and structural parts materials

- For smooth surface to special treatment

- TPE flow length/product thickness ratio is less than 150:1

- Use a good adhesive.