“Sheet metal” is a kind of comprehensive processing technology of sheet metal of uniform thickness, including shearing, stamping, bending, forming, welding, splicing, etc. It has been widely used in automobiles, home appliances, consumer electronics and other major fields, and can be seen everywhere in our daily life. Sheet metal products, compared with plastic products, there is no complex surface, there is no fancy command in the software design sheet metal module, but everywhere tests the designer’s understanding and familiarity with the process. This article will meet the needs of the backstage message partners to share the knowledge of sheet metal bending.

Sheet metal design difficulties, functions

Although there is no complex curved surface shape, Sheet metal products are neat and have their unique characteristics. Is the difficulty of its design specific we can be summarized as follows:

① How to fully consider the requirements and characteristics of processing technology in the structural design of thin plate members.

② In the design of sheet metal parts, we must take into account the manufacturing and processing, in punching, cutting, bending, stretching processing of the degree of difficulty, as far as possible to make the processing easy, and can make the material saving, but also can increase the strength, and not waste.

Sheet metal process - bending

In sheet metal processing technology, although there are many processes, the most common or the most important is bending; sheet metal bending seems simple; there are also a lot of doors and skills; here we will focus on sheet metal bending process skills:

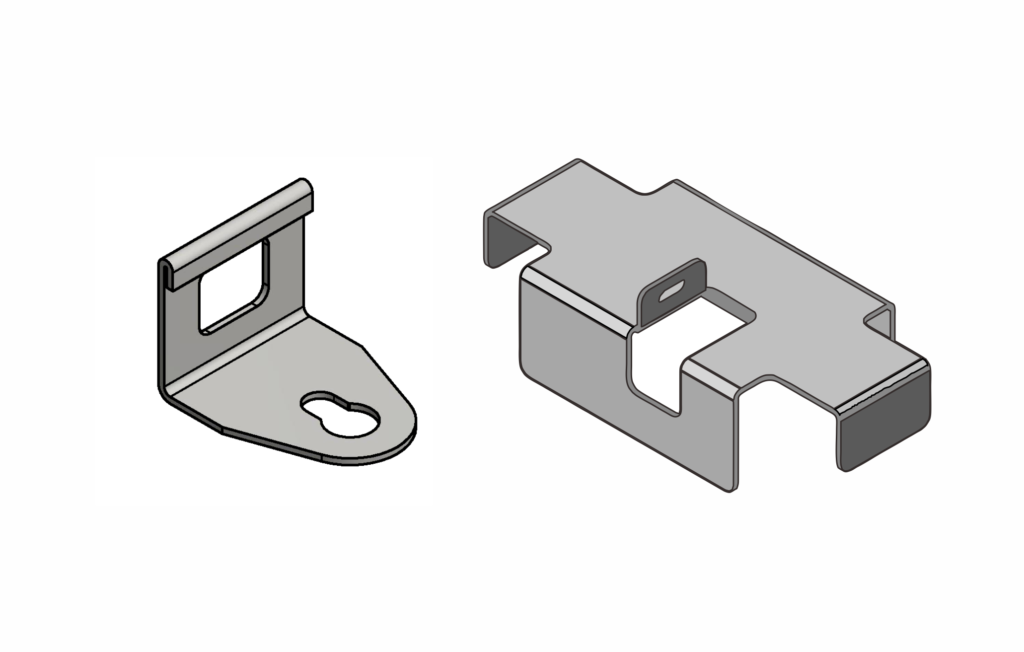

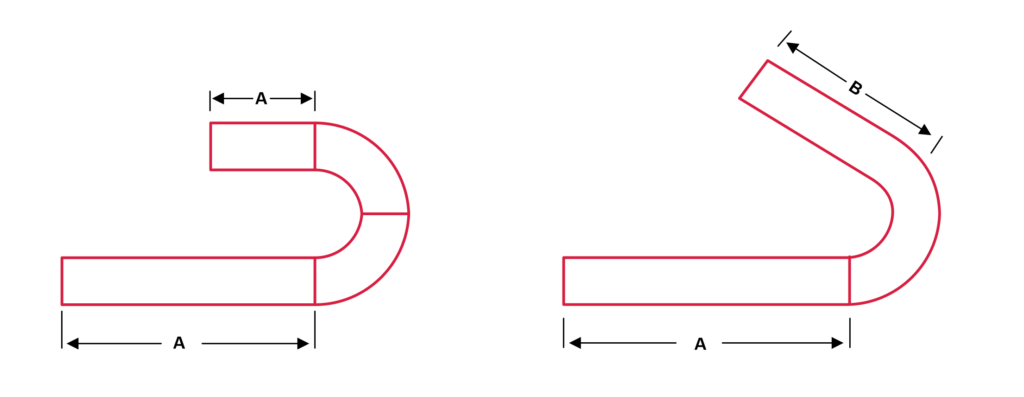

The figure below shows that this is the most common bending structure. It is also a more common bending structure, figure 1 and Figure 2) compared with the special point is added on both sides at the edge of the bending process mouth add (sheet metal module: separation of continuous wall crack arrest groove), its biggest role is to avoid processed products following bending deformation.

When it comes to bending, we will inevitably refer to the bending modes of different structures:

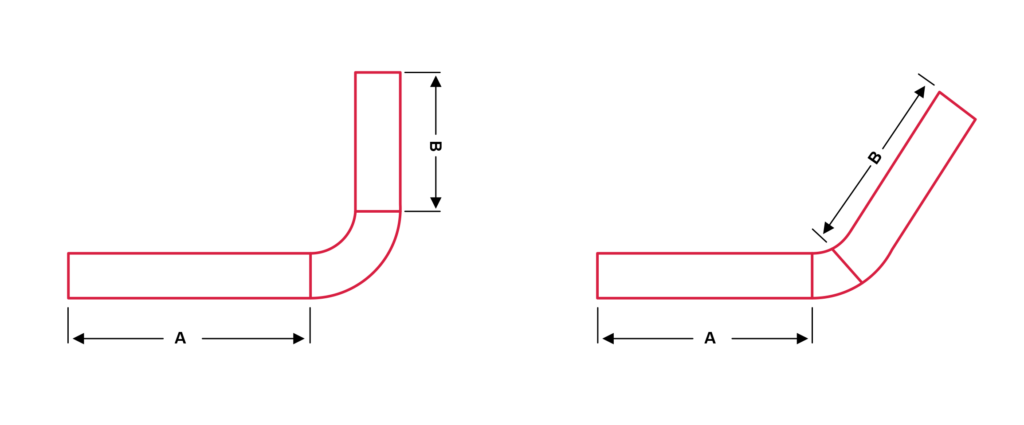

① General bending

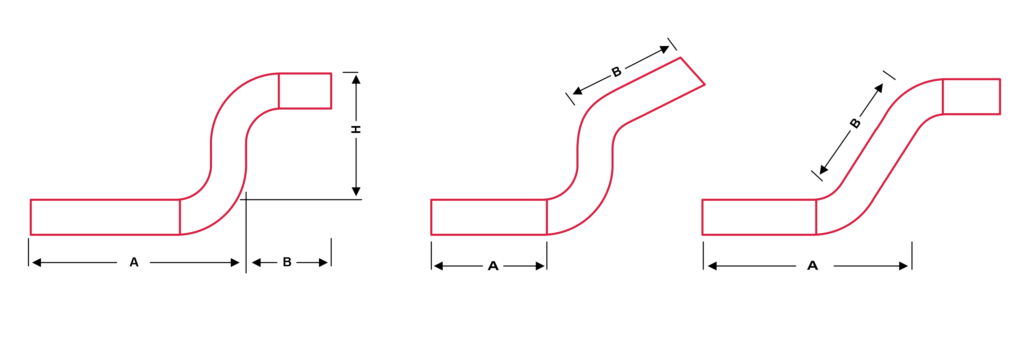

② Z bending

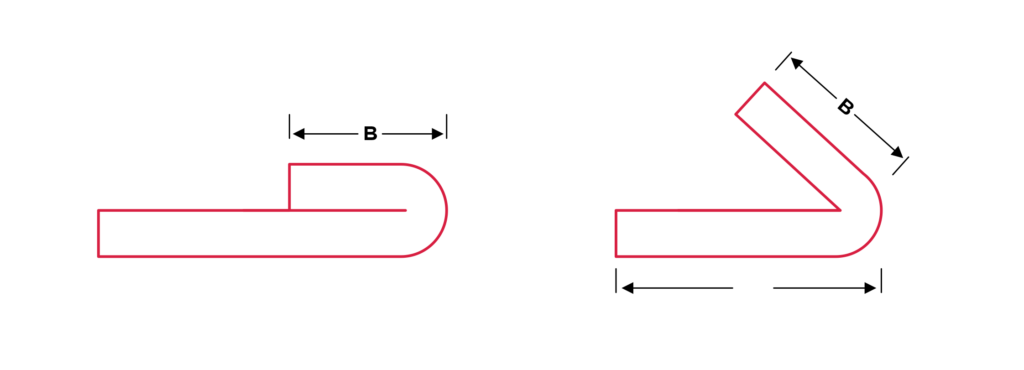

③ Fold back/press down the edge

④ N bending

Minimum bending height:

The minimum bending edge at a time

Reference table for R and minimum bending height of cold rolled sheet steel

| Items | Material thickness | Groove die | Terrace die | Min bending height |

| 1 | 0.5 | 4 | 0.2 | 3 |

| 2 | 0.6 | 4 | 0.2 | 3.2 |

| 3 | 0.8 | 5 | 0.8 / 2.0 | 3.7 |

| 4 | 1.0 | 6 | 1.0 / 0.2 | 4.4 |

| 5 | 1.2 | 8 / 6 | 1.0 / 0.2 | 5.5 / 4.5 |

| 6 | 1.5 | 10 / 8 | 1.0 / 0.2 | 6.8 / 5.8 |

| 7 | 2.0 | 12 | 1.5 / 0.5 | 8.3 |

| 8 | 2.5 | 16/14 | 1.5/0.5 | 10.7 / 9.7 |

| 9 | 3.0 | 18 | 2 / 0.5 | 12.10 |

| 10 | 3.5 | 20 | 2 | 13.5 |

| 11 | 4.0 | 25 | 3 | 16.5 |

pay attention:

① The minimum bending height includes a material thickness.

② When V bending is an acute Angle, the shortest bending edge should be increased by 0.5.

③ when the parts material is aluminum plate and stainless steel plate, the minimum bending height will have a small change, aluminum plate will be a little smaller, stainless steel will be a little bigger

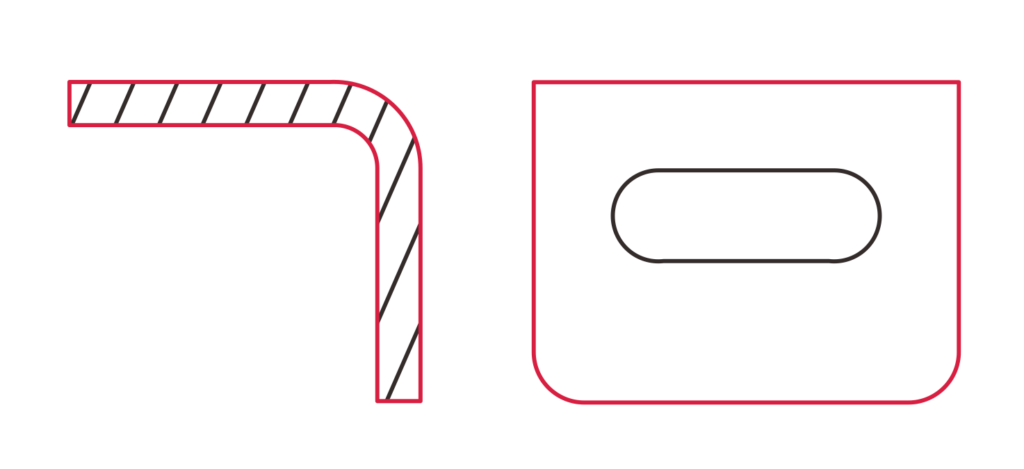

Minimum distance between hole and long round hole and bending edge

The hole edge at the bending is too close to the folding line, so the material cannot be taken up when bending, resulting in the deformation of the hole shape, so the distance between the hole edge and the folding line is very important

(1) round hole

Minimum distance between round hole and bending edge

Thickness of sheet metal 0.6 ~ 0.81.01.21.52.02.5 minimum distance X1.31.51.72.033.5

(2) long round hole

Minimum distance between long round hole and bending edge

L<2626 ~ 50>50 X2t+ r2.5t +R3t+RPS: