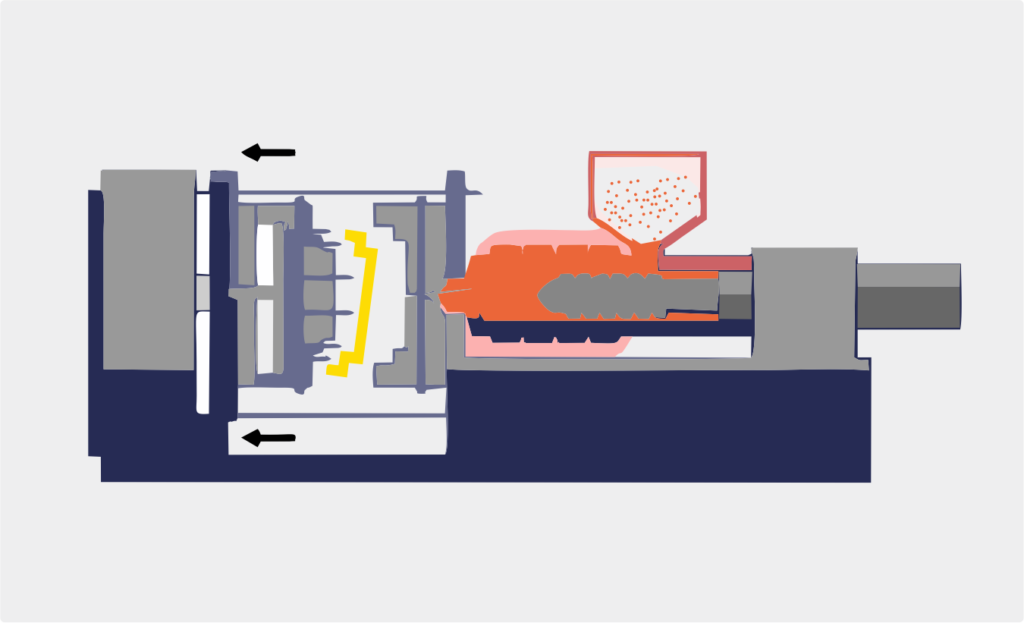

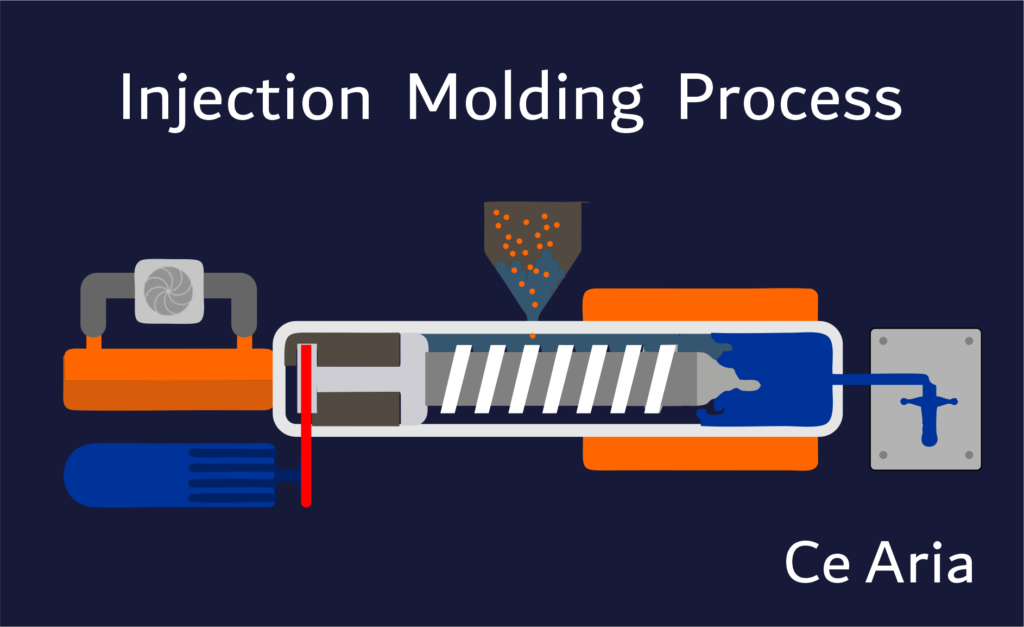

Plastic injection machine is the main equipment of injection molding, it can heat thermoplastic or thermosetting plastic in the plasticizing cylinder, mixing, plasticizing, to melt state, to have plasticized good material pressure, injection and injection mold cavity, by cooling solidified products.

Injection molding machine is mainly composed of injection system, mold closing system, hydraulic system, electrical system, in addition to heating and cooling system, lubrication system, safety and monitoring system

1. Clamping system

The clamping system mainly includes clamping device, adjusting device and ejector device.

The main functions of the mode-locking system are:

(1) Ensure that the mold can close, open and push out products quickly, flexibly, accurately and safely;

(2) The mold closure is. Provide enough clamping force to resist cavity pressure caused by injection melt and prevent the mold from expanding

2. Injection system

Injection system mainly includes pre-plastic device and injection device, so also known as pre-plastic, injection system. Its main functions:

(1) uniform heating, and in the specified time will be a certain number of molten plastic plasticizing;

(2) A certain amount of melt is injected into the mold cavity at a certain pressure and speed;

(3) After the injection, the melt in the mold cavity is kept under pressure.

3. Hydraulic control system

The hydraulic control system of injection molding machine is mainly composed of various hydraulic components, circuits and hydraulic auxiliary components. Its main function is to ensure that the injection molding machine can work accurately and effectively according to the predetermined technological conditions and action procedures

4. Electrical control system

Electrical control system is mainly composed of various electrical and electronic components, instruments, heaters, sensors and so on. Its main role is: with the hydraulic control system, accurately achieve the predetermined process requirements; Provides power for the realization of an action program

5. Heating and cooling system

It is mainly used for heating the barrel and nozzle. The cooling system is mainly used for cooling the feeding section of the mold, hydraulic oil and the barrel.

6. Lubrication system

Lubrication system is to provide lubrication conditions for the parts of the injection machine with relative movement, such as template adjustment, mold adjustment device, connecting rod machine twist, etc.;

7. Security and detection system

The safety protection device of injection machine is mainly composed of safety door, travel valve, mechanical protection rod and so on. The main role is to protect the personal safety of operators and equipment operation safety;