Plastic parts manufacturing process, according to the need to first plastic molding, processing into all kinds of plastic semi-finished products or parts, injection molding is one of the main plastic parts molding methods. Injection molding must use an injection molding machine and other molding equipment and injection mold to complete. For injection molding principle and process and injection mold structure and principle and other theoretical content in other relevant information are detailed description, need not repeat here.

In the manufacturing process of plastic products, plastic forming is one of the most important contents. Plastic forming is a process in which plastics in various forms (powder, granule, melt and dispersion) are made into products or blanks of the desired shape. Plastic parts molding is based on injection molding, extrusion and calendering, three molding processes. Plastic product manufacturing and injection molding process is the most common.

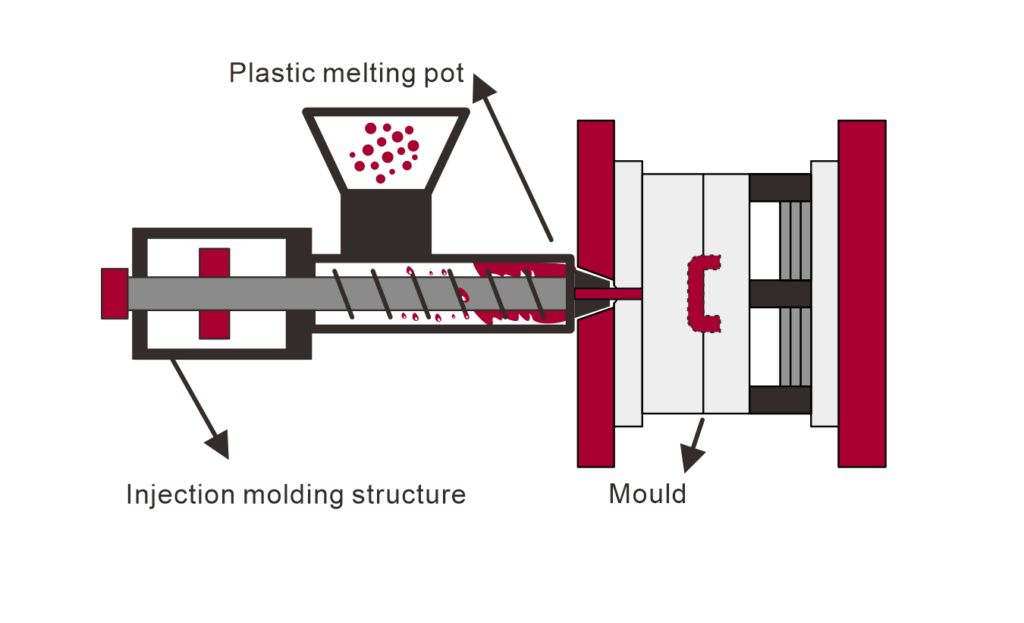

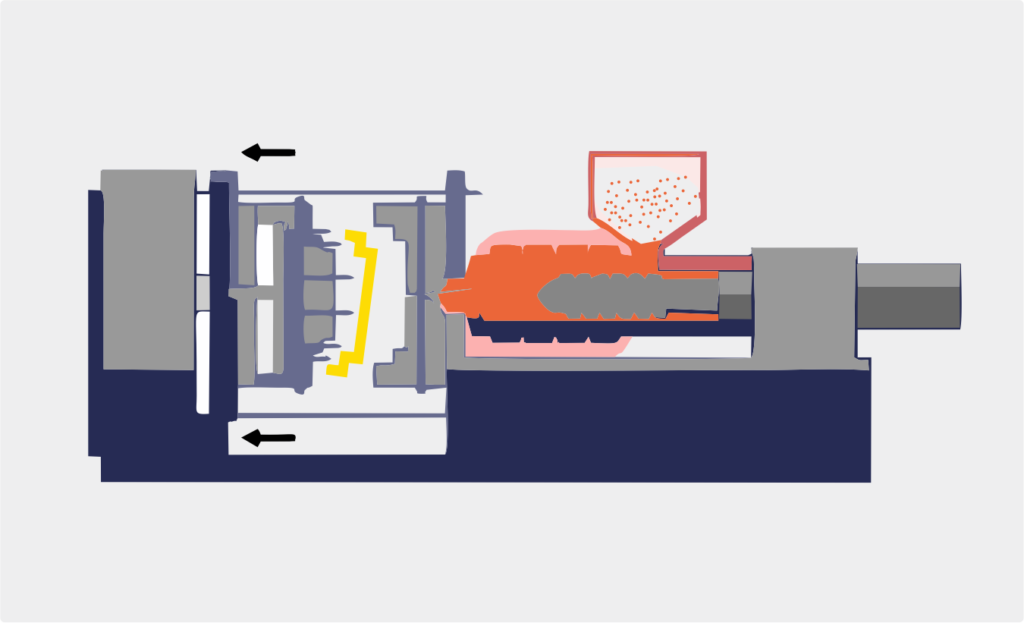

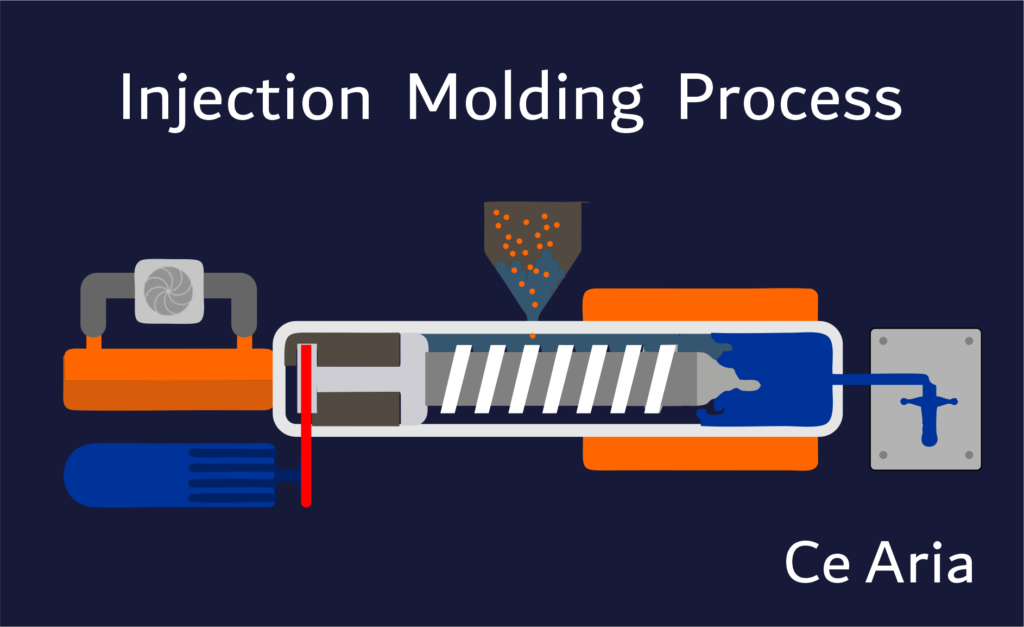

The so-called injection molding refers to the injection of heated molten material into the mold, after cooling and curing, to get the molding character method. Is the specific process, from the granular or powdered plastic injection molding machine hopper into heat in the cylinder, the heated plastic into molten state, by putting pressure on the screw and cylinder through the end of the nozzle injection of low temperature, the closure of the classics in mold cavity cooling hardening and keep the shape of the cavity has given, mould remove colloid was completed after a work cycle.

Injection molding is a common method used in plastic molding processing. It is suitable for all thermoplastics (thermoplastics: Plastics that can be repeatedly heated, melted and cooled to harden within a specific temperature range, such as ABS, PP, PE, PC, PA, POM, and some thermosetting plastics, plastics most of the parts of plastic products are made by injection molding. The injection moulding cycle is short (a few seconds to a few minutes), and the quality of the molding products can be from a few grams to dozens of kilograms. It can be moulded with complex shapes, precise sizes and metallic or non-metallic inserts at a time. Therefore, the method has strong adaptability and high production efficiency.

The disadvantage is that the mold cost is high, and it is difficult to clean up, so small-batch products should not use this method. The products formed by this method are TV shell, semiconductor radio shell, electrical connector, knob, coil skeleton, gear, car lamp cover, teacup, rice bowl, soapbox, bathtub, sandals, etc.