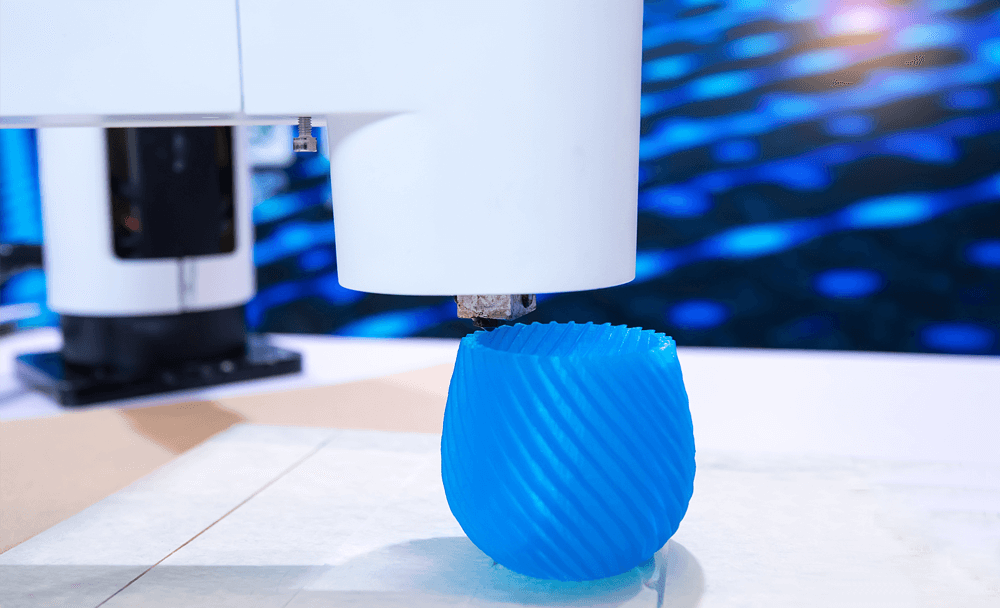

How To Clean a 3D Printer Bed?

In a 3D printer, the print bed is a surface on which the print head places the model that is being printed at that moment. The print bed always needs to be flat surface and clean. Since it is an essential part of a 3D printer, it must always be a clean and flat surface. […]

How To Clean a 3D Printer Bed? Read More »