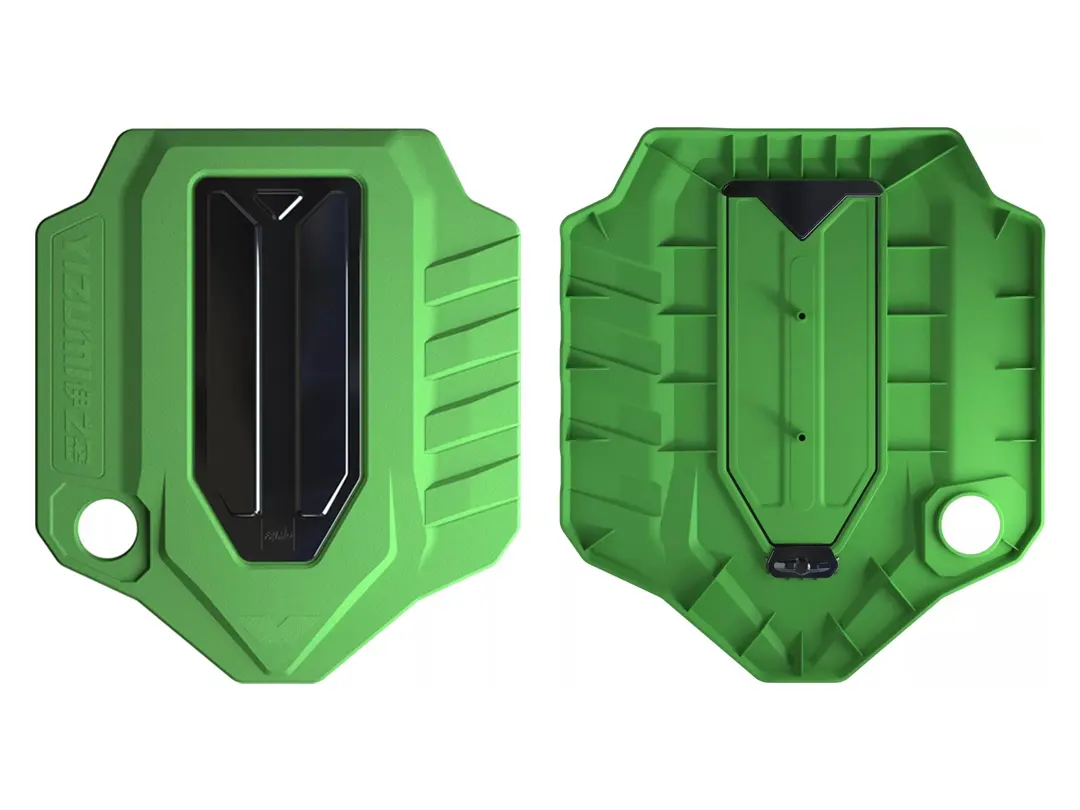

Monochrome injection mold, as the name implies, is an injection mold that can only be injected one colour at a time; And a double colour injection mold, is an injection mould of two colours.

Overmolded products, not only two or a variety of color plastic simple combination, and in the product precision, beautiful appearance, different color plastic better fusion, and product molding cycle on the injection molding machine has put forward higher requirements, and monochrome injection molding products are relatively single. Inner and outer plastic products can replace the secondary processing to a molding. Monochrome injection products do not have this function.

Overmolding products, because of different color combinations, can give old products (mold) new life. The core material can use low viscosity raw material to reduce the injection pressure. Corresponding dual-colour injection molding machines can also be used to produce monochrome products, one machine dual-use to provide diversified functions and all-around services. Core materials can be recycled waste or low-quality raw materials to reduce costs. Cortical material can use high quality with special surface properties or electromagnetic interference and other materials to increase product performance. The proper combination of cortex and core materials can reduce residual stress and increase product strength.

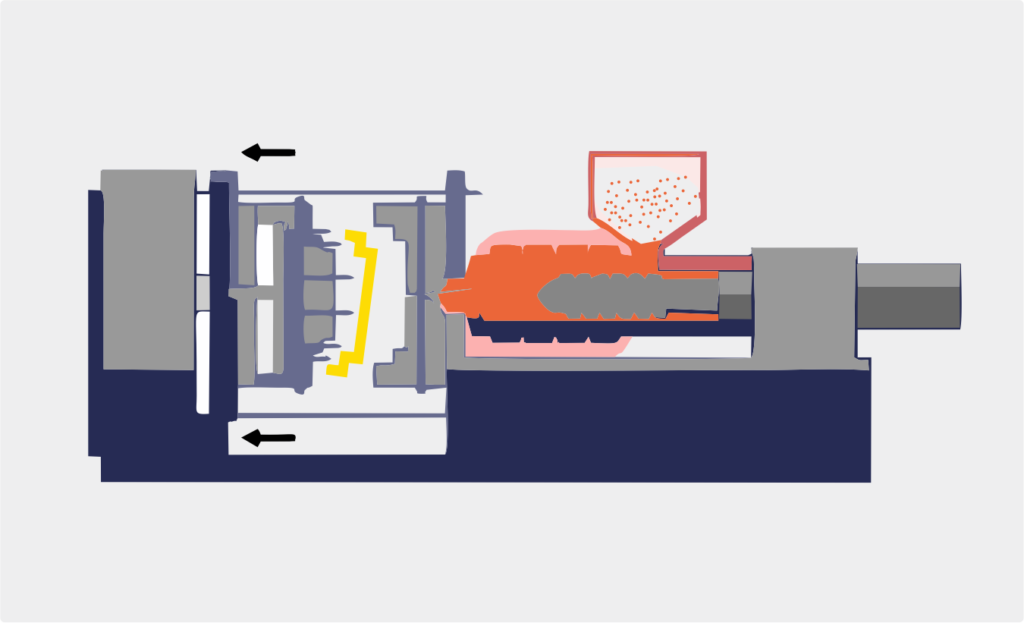

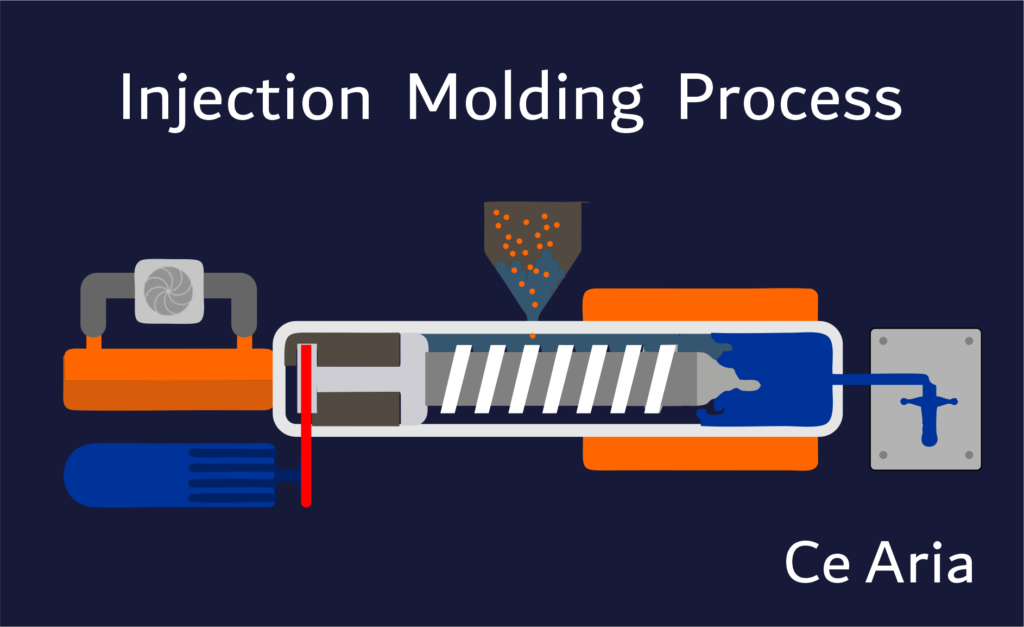

The injection moulding process is no different for double color injection molding products and monochrome injection molding products detection. The main detection basis is customer requirements. The two-color injection molding machine and mold structure is more complex than that of single-colour injection molding machine and mold.

The advantage of overmolding

1. Diversified selection of product design

Double-color injection molding can focus various functions on a plastic part, such as soft surface, ergonomic design, two-color appearance, waterproof, sound insulation and noise reduction, shock absorbent, moisture-proof and anti-skid, can save design space and reduce the total number of parts and components.

2. Reduce the number of projects and control costs

Although the cost of the two-color mold is more expensive than that of the monochrome mold, the injection process can realize the rapid molding of two plastic parts, which can reduce the time cost and labour cost of injection molding improve efficiency.

3. Different plastics are integrated into one according to organic chemical connection, with a more coordinated appearance, high quality and stronger compressive strength.

4. The two-color mold needs to be matched with the injection molding machine, and the precision of the two-color injection molding mold and injection molding machine should be higher.

Defects or constraints of overmolding

1. Compatibility between two plastics

Because different plastics physical properties are different, the compatibility mode will directly affect the combination of the two materials, the lack of combination, etc. Not all plastics have a very good compatibility mode. Material selection is very important.

2. Plastic shrinkage rate difference is small

Too much difference will harm the compressive strength of the contact surface and is likely to lead to the expansion and contraction of goods.

3. The overmolding can not produce the too complex structure of the product