TPE elastomer material has excellent comprehensive properties and is a soft material used in molding and double color injection molding production process. TPE is usually called SEBS modified by composite functional materials in the elastomer industry. What are the advantages and problems of TPE material for overmolding?

一. The common overmolding materials

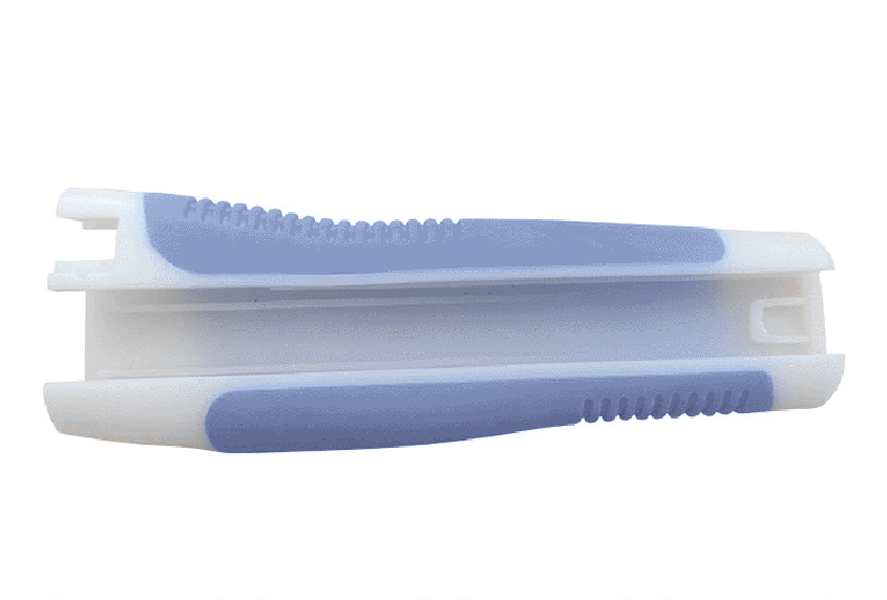

TPE can be used for cladding and two-colour injection molding. TPE is usually matched with hard materials, mainly plastics, metals, and fabrics, as soft materials. TPE + cloth is mainly used for luggage products. The process is the same as metal cladding, usually false cladding. And the real coating molding in secondary injection molding and double-colour injection molding is more common.

TPE can be firmly bonded with some commonly used plastics PP, GPPS, HIPS, ABS, and engineering plastics PC, PC/ABS, PA, and modified materials. Adhesion between TPE and POM is still a problem in the current elastomer industry. Since the solubility parameter SP(22.6) of POM differs greatly from that of TPE (7.2-7.6), the two materials are incompatible, and no suitable compatibilizer has been found to promote the bonding of the two materials.

二. The advantages of TPE material for overmolding

1. TPE can be adjusted to appropriate hardness (hardness range is shaw 25-90A) and appropriate physical properties (such as wear resistance, adhesion, melting index, etc.). Product attributes provide various possible material applications for various products.

2. TPE after cladding molding processing is often used in handles, grips, and electronic products. The material gives the product excellent touch, enhances the grip, enhances the aesthetic feeling of the product and the added value of the product. Most of the products are exported to the United States, Japan, the European Union, and other developed countries and regions. TPE elastomer soft, green raw materials, materials do not contain phthalates, halogen, in line with ROHS environmental testing standards, can fully meet the United States, Japan, the European Union, and other developed countries and regions’ environmental conditions protection requirements.

3. Because TPE material has good skid resistance and good elastic touch, it can enhance the touch of the product and is conducive to grip.

三. The defects of adhesives

Lack of material: improve injection temperature; Increase injection pressure, improve material fluidity.

Split, overflow edge: injection molding temperature is low; Increase clamping pressure; Reduce injection pressure; Reduce fluidity from a recipe perspective.

Dull surface, not bright: improve injection molding processing temperature; Dry the material, reduce the moisture of the raw material.

Viscosity difference: completely baked before injection molding; Improve injection temperature; Adjust the recipe.

Product injection deformation: strengthen mold cooling; Appropriately extend the pressure holding time.

Product stick mold: add release agent or lubricant (for internal lubricant – release agent should pay attention to the additional amount to prevent release agent precipitation and removal.)

The problems needing attention in TPE viscose injection molding

1. Avoid sharp corners in the design, ensure good contact between TPE and hard plastic, enhance the bonding effect;

2. Keep the TPE melt temperature to ensure the bonding effect;

3. the choice of masterbatch carrier resin compatible with TPE and structural materials;

4. TPE should have good fluidity, TPE molding thickness and size ratio is very small, TPE usually need to flow through the long path and thin wall area to fill the mold;

5. TPE should be dried after processing materials in order to reduce the surface watermark, to obtain a uniform surface colour effect;

6. special treatment of the smooth surface, the purpose is to increase the adhesion of soft and hard material bonding surface, enhance the bonding effect;