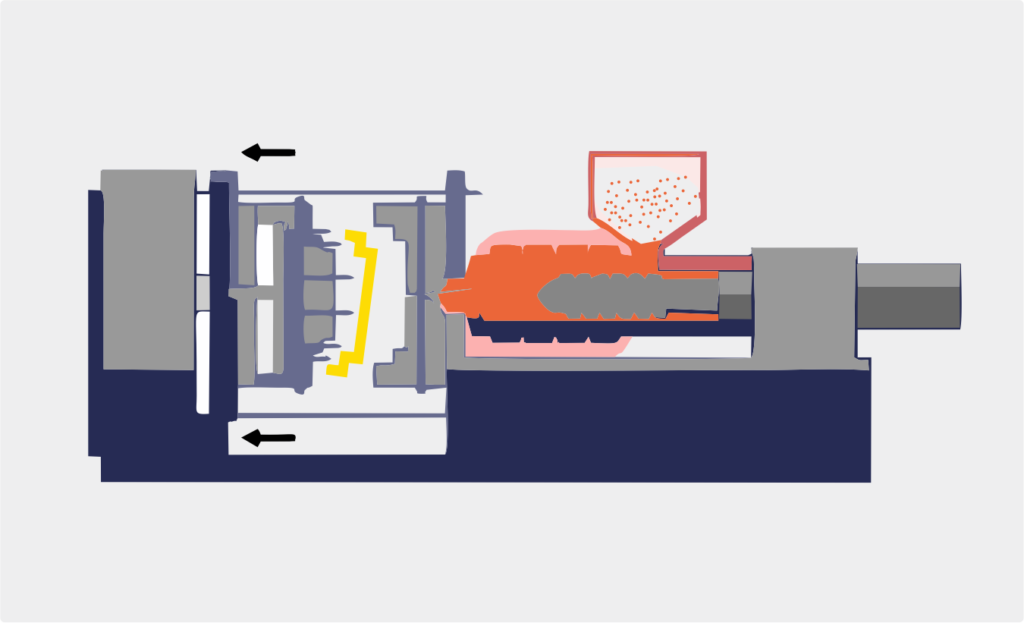

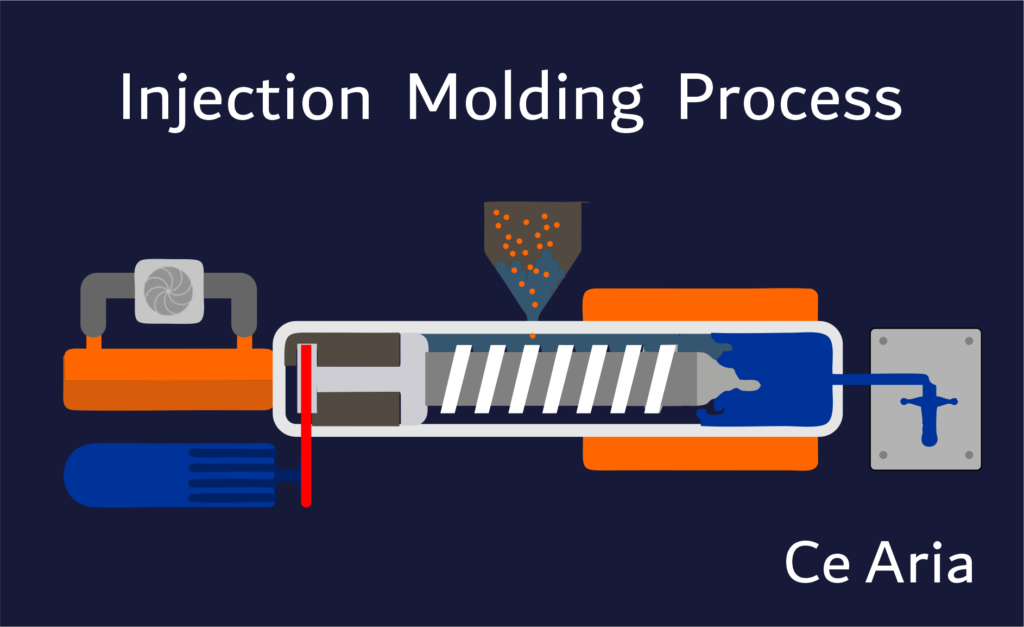

Overmolding refers to the injection of two different materials into the same set of molds to achieve the molding process of the product formed by two materials. Two kinds of materials have plenty of color different, have plenty of soft hard is different, can improve the beauty of the product and the performance, such as assembly.

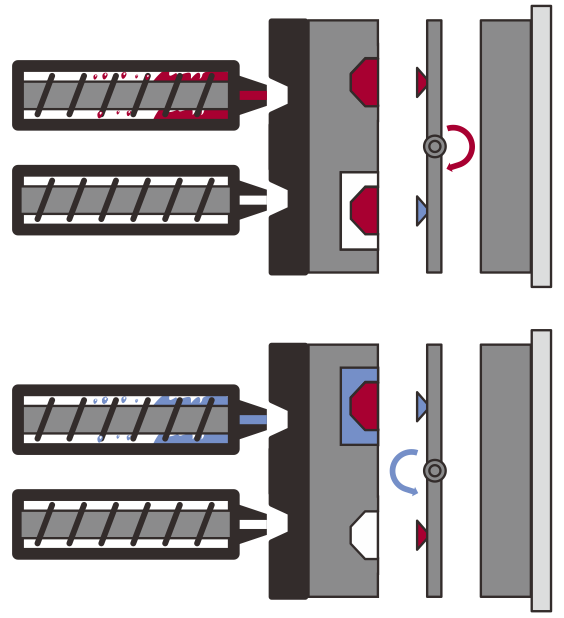

Overmolded products need two male and two female moulds, the first injection molding in the male and the first female mold. After molding, open the mold without demoulding and directly change to the second female mold. Second injection molding, demoulding can get two-colour injection finished products.

The matching material of double color injection molding must meet two basic compatibility conditions, namely, adhesion compatibility and processing compatibility. The melting point of the two materials must have a certain temperature difference, 60℃ is generally recommended, and at least 30℃ is recommended. The melting point temperature of the first shot material is high. Generally, the first shot is PC or PC/ABS, and the second shot is TPU or TPE. PC is 0.6-0.7mm thick, and the software is more than 0.4mm.

Widen the contact area as far as possible, make grooves, and increase the adhesive force. The first shot with pulling core, the second shot part of the material injection into the first shot inside, the first shot mold surface as far as possible do rough.

Design guide for Overmolding

- The two shapes of the mother mold must be different, respectively forming a product, and the two shapes of the male mold should be the same;

- The front and back die of the mould must be matched after rotating 180° at the centre;

- We must carefully check the maximum modulus thickness, minimum modulus thickness, KO hole distance, etc.

- the three plate mould nozzle can be designed to automatically demolding action;

- In the second injection mold design, a good product, rubber, can be designed to avoid space to avoid the second mould scratching the first time. However, the strength of each sealing position must be carefully considered;

- injection molding, the first injection molding product size can be slightly larger to make it in the second molding can be pressed more tightly with another public mold, to achieve the role of sealant;

- pay attention to the second injection molding; plastic flow will impulse the first time has been moulded products, so that the rubber deformation;

- Before the A and B plate closes the mold, pay attention to whether the sliding block or inclined top of the front mold will be reset first and crush the product;

- The water transport arrangement of the two female and male models is as full as possible and balanced;

- 99% of the time, the hard glue part of the injection product is first injected, and then the soft glue part of the injection product because the soft glue is easy to deformation.

The overmolding process has now been widely used in automobiles, electronic products, power tools, medical products, household appliances, toys and almost all plastic fields.