3D Printing VS Injection Molding

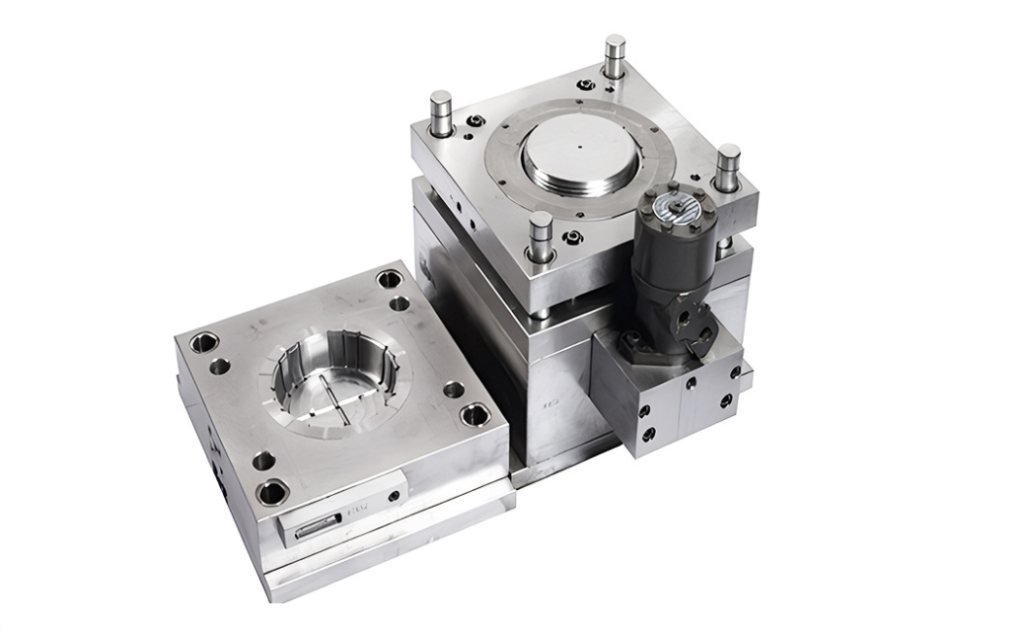

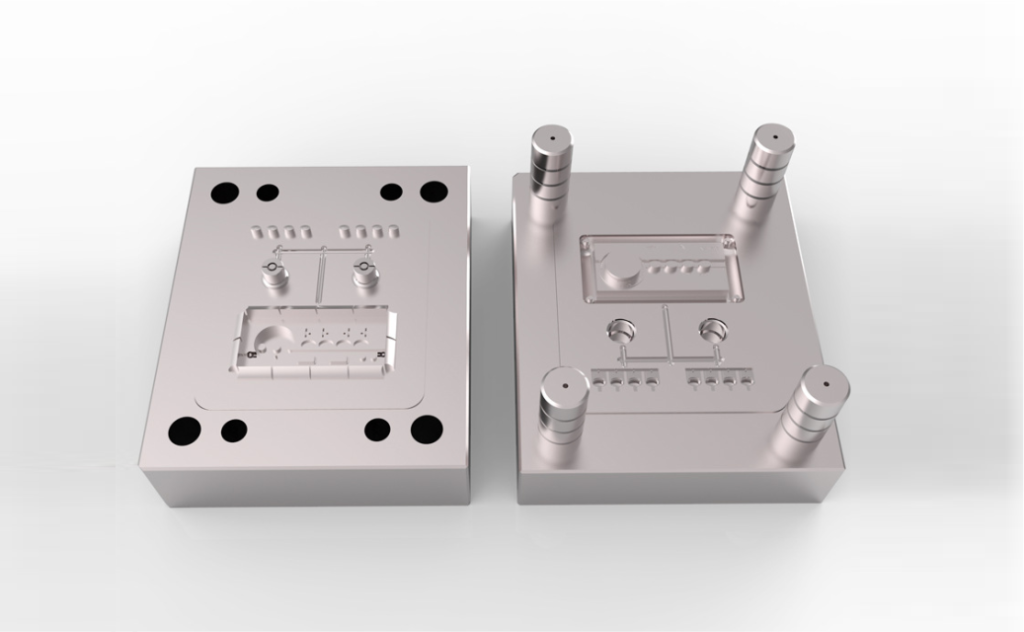

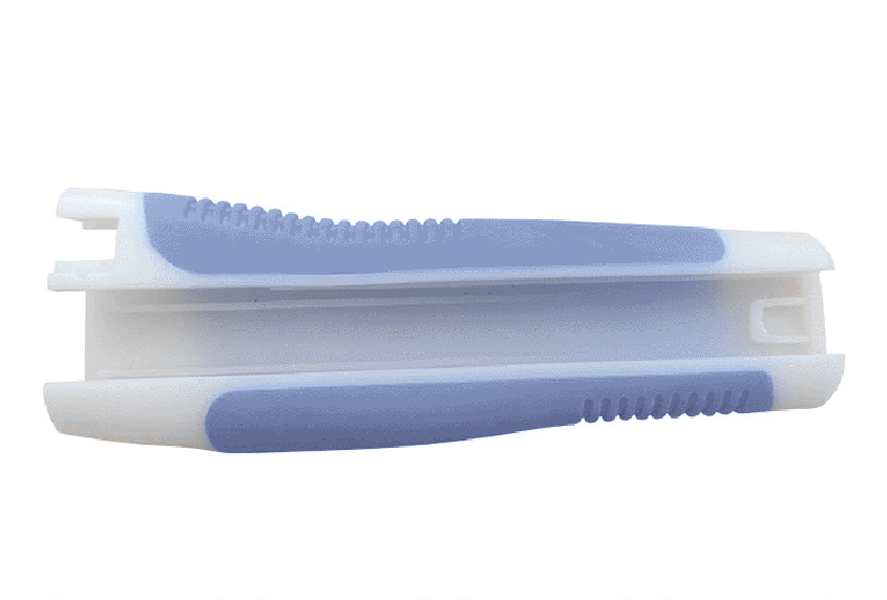

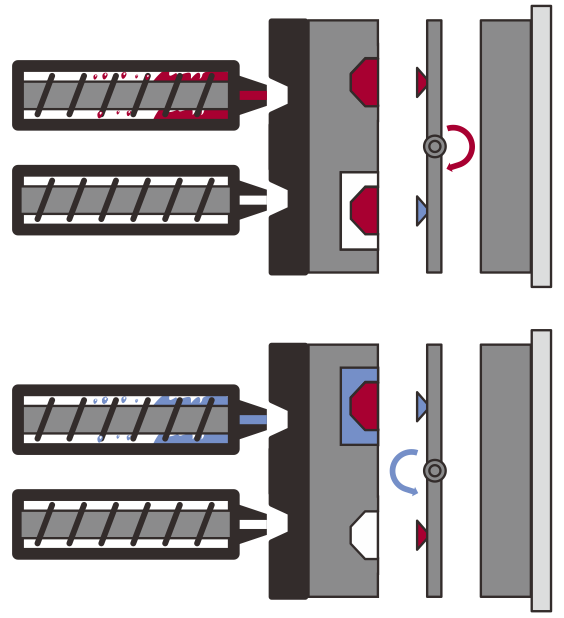

Plastic injection molding is to point to fall in a certain temperature, through screw agitate the plastic material that melts completely, shoot into the mold cavity with high pressure, after classics cooling solidifies, get the method that shape article. The process began in the 1920s, and has nearly a hundred years of development history, and …